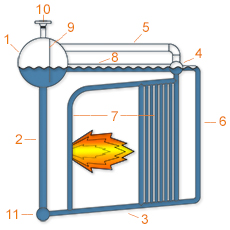

Water Tube Boiler- ERK-HP

The SCHNEIDER ERK-HP is a natural circulation boiler in corner tube boiler design and is manufactured as a steam and hot water generator. With both boiler types, the tubular body is constructed in the same way – namely from prefabricated tubular elements containing combustion chambers and contact heating surfaces. This structure makes it fundamentally different from the conventional water tube boiler with natural circulation. This is because it has been built as a multi-drum boiler with heated downpipes for over 100 years

Benefits of the ERK-HP

- Use of various fuels

- Extremely high load change speeds with stable water level

- Compact design and self-supporting boiler construction

- Generation of completely dry steam

- Ideal adaptability to the spatial possibilities of the floor plan

Areas of Application

- Food industry

- Oleochemical industry

- Pharmaceutical industry

- Oil and gas industry

- Energy supply